Among those "in the know" a variety of terms are used to reference specific styles of watch bands similar to our NATO® Style Straps. For example, 'G10' NATO® straps commonly have two metal rings to secure the free end of the strap, whereas 'RAF' NATO® straps instead have a nylon loop to secure the loose end. Our design team unanimously felt that the nylon catch of the RAF strap was cleaner looking, more functional and overall more appealing than the additional metal lugs. As a result, our bands were designed with a nylon catch similar to what you might find on RAF straps. However, RAF straps are usually missing the locking feature that properly secures the watch head in place on G10 straps. This attribute is essential to assure that the watch holds its position on the wrist and that the watch head does not fall off the band while it is being put on or taken off of the wrist. A damaged watch can cost thousands of dollars to repair and a whole lot of frustration, so you will find the locking feature remains intact as an important element of our products. The result is a quality watch band that is truly unique.

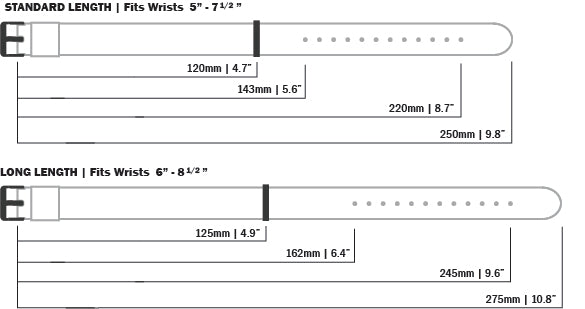

Our Nylon NATO® style bands are available in two lengths. The original or 'standard' length (10") generally fits wrists from 5" to 7 1/2" in circumference and is available in widths of 18mm, 20mm and 22mm. The 'long' version (11") generally fits wrists from 6" to 8 1/2" and is available in 20mm, 22mm and 24mm widths. Those with wrists under 7" typically prefer the 'standard' length band and those with wrists over 7 1/4" typically prefer the 'long' band. If you do encounter a fit issue after purchase, we offer a money back guarantee!

When designing these high quality watch bands, we studied several statistical analyses on the distribution of wrist sizes among various populations. The result is a band that accommodates not only a wide variety of watch designs, but also wrist circumferences covering over 95% of the general population.

The weave of our ballistic nylon was selected for its comfort and durability. Our customers often tell us that Barton bands are softer and more flexible than their other nylon watch bands, yet maintain their durability just as well. Our nylon is lightweight and breathable, yet very sturdy... and it has been laser cut to reduce or eliminate fraying. The 1.2mm thickness allows for ample room to slide the strap between the watch head and spring bar of most timepieces.

Our watch bands use stainless steel components where some others use iron. Iron components rust and need to be bulkier and heavier to achieve strength comparable to that of stainless steel. The finish on iron parts can weather or wear off, leaving a dull, scrap-metal appearance. If you take a knife to our stainless steel components, you will find a material that 1) is solid all the way through, 2) is difficult to scratch or bend and 3) maintains its initial shine for many years.

Our basic Nylon NATO® straps utilize ultrasonic welding where others use glue. The ultrasonic welding process joins two adjacent pieces of nylon webbing into one homogeneous material at the point of contact. It yields a product that is generally stronger and more reliable than both glue or stitching, while also leaving a cleaner look (no stitching running across the band). There are no solvents, adhesives or other consumables required and it consumes very little energy.